2025-11-24

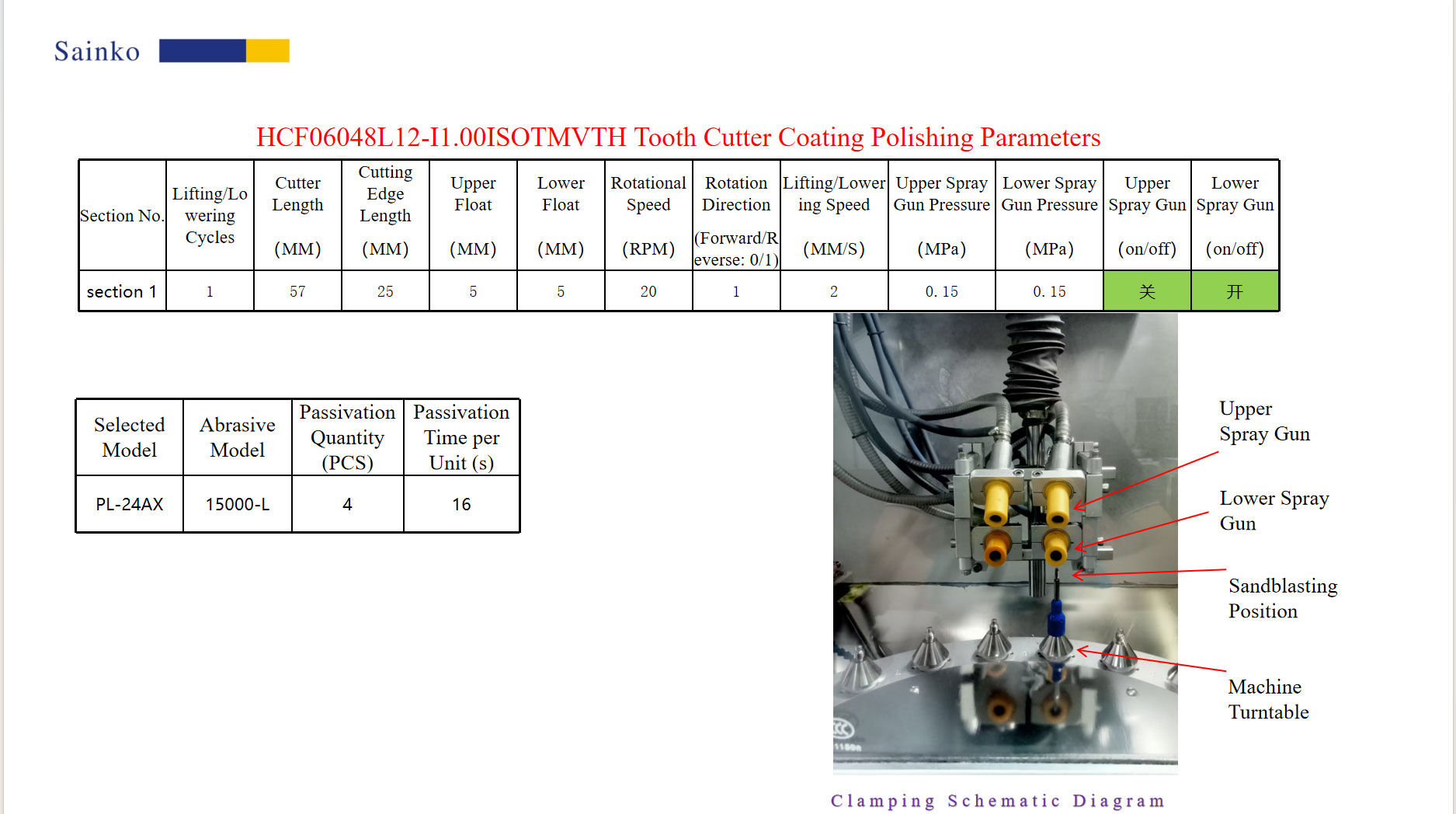

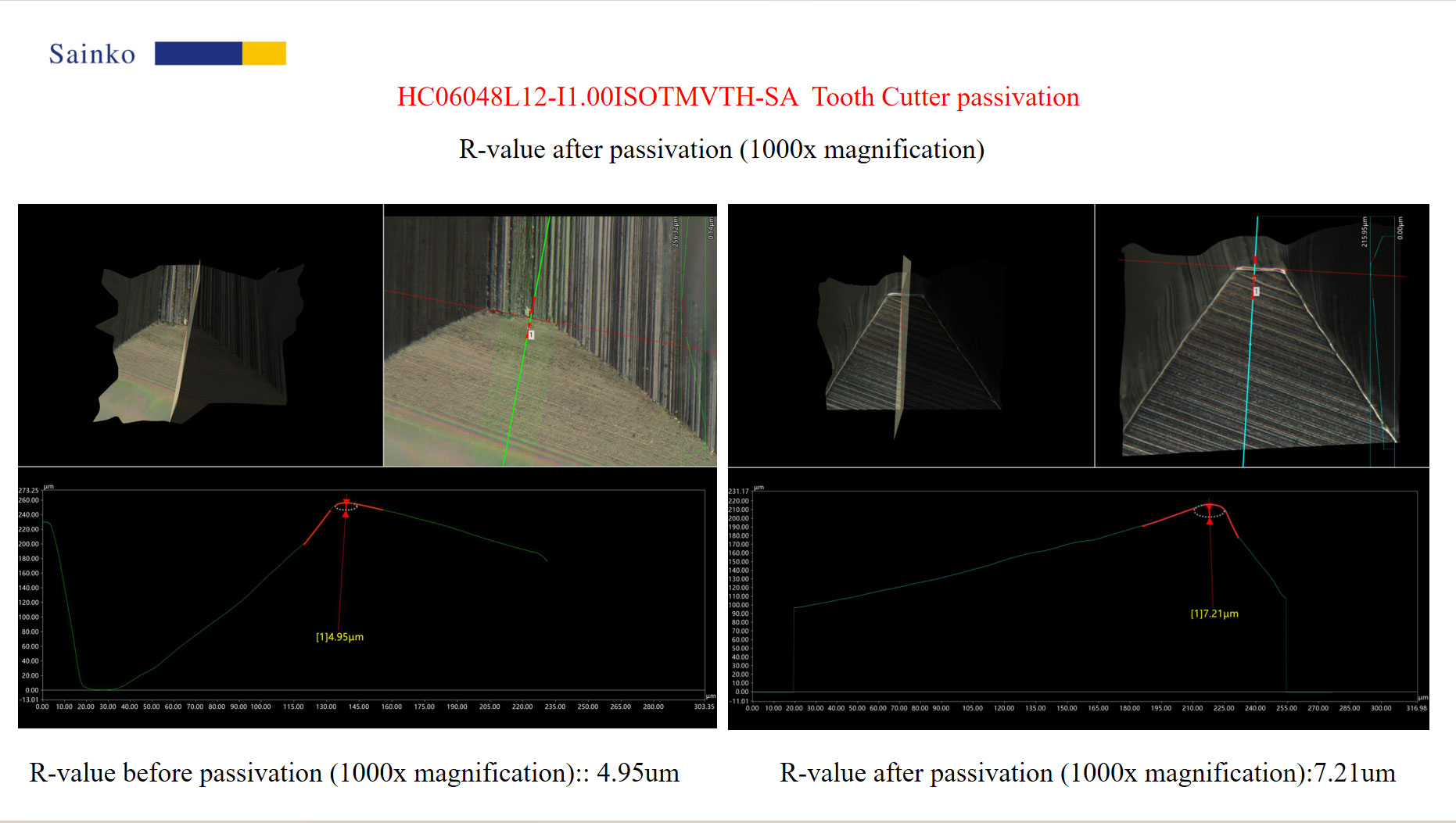

2025-11-24During the processing, precise control of process parameters such as passivation speed (20 RPM), up and down float (5 mm), lifting speed (2 mm/s), and spray gun pressure (0.15 MPa) is achieved through equipment. A two-stage sandblasting process is used to ensure uniform force distribution on the cutting edge and meet passivation requirements. Through precise control of the equipment and efficient coordination of abrasives, the passivation values of the cutting edges of the 5 milling cutters have consistently reached the preset standard of 7 μ m, effectively removing the original serrations and burrs on the cutting edges.

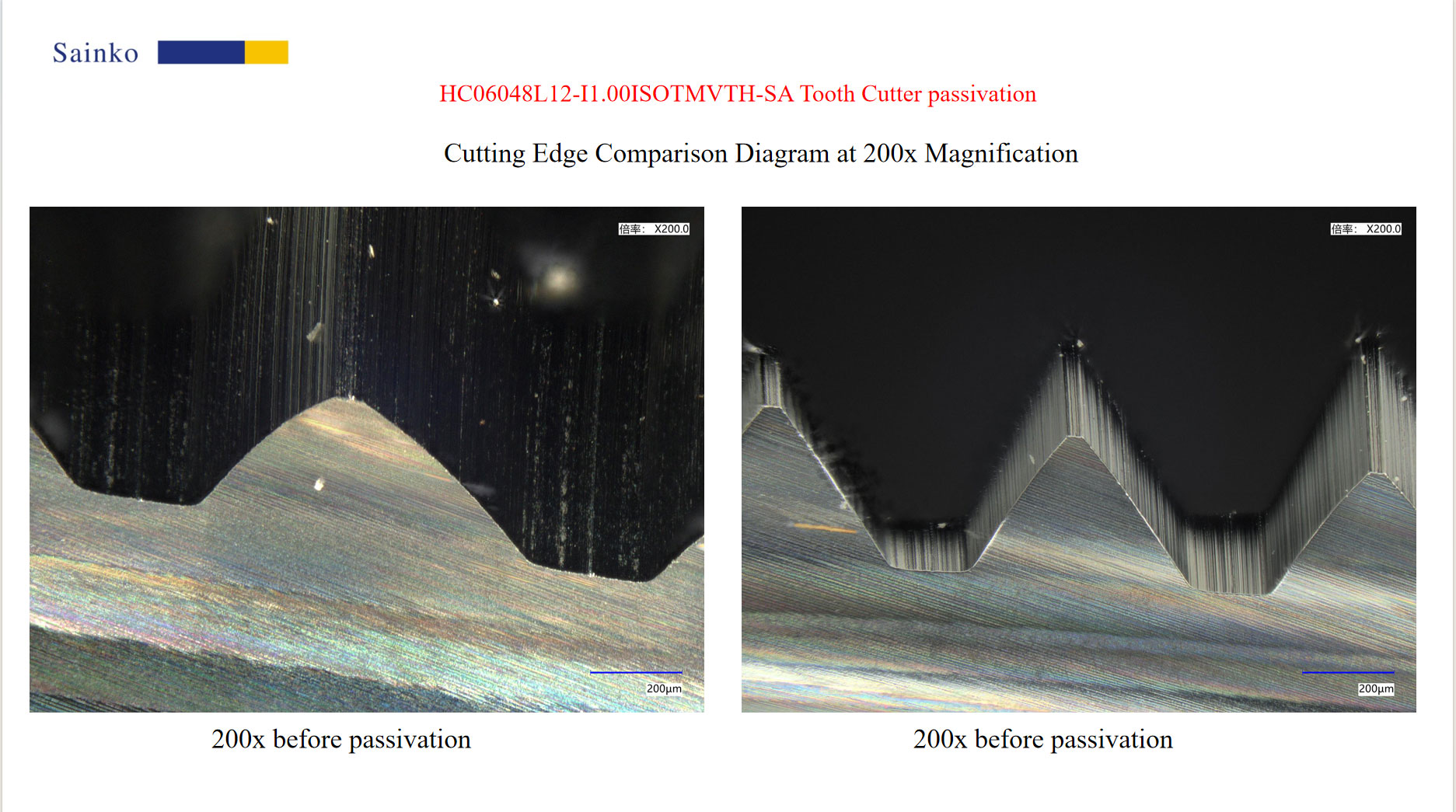

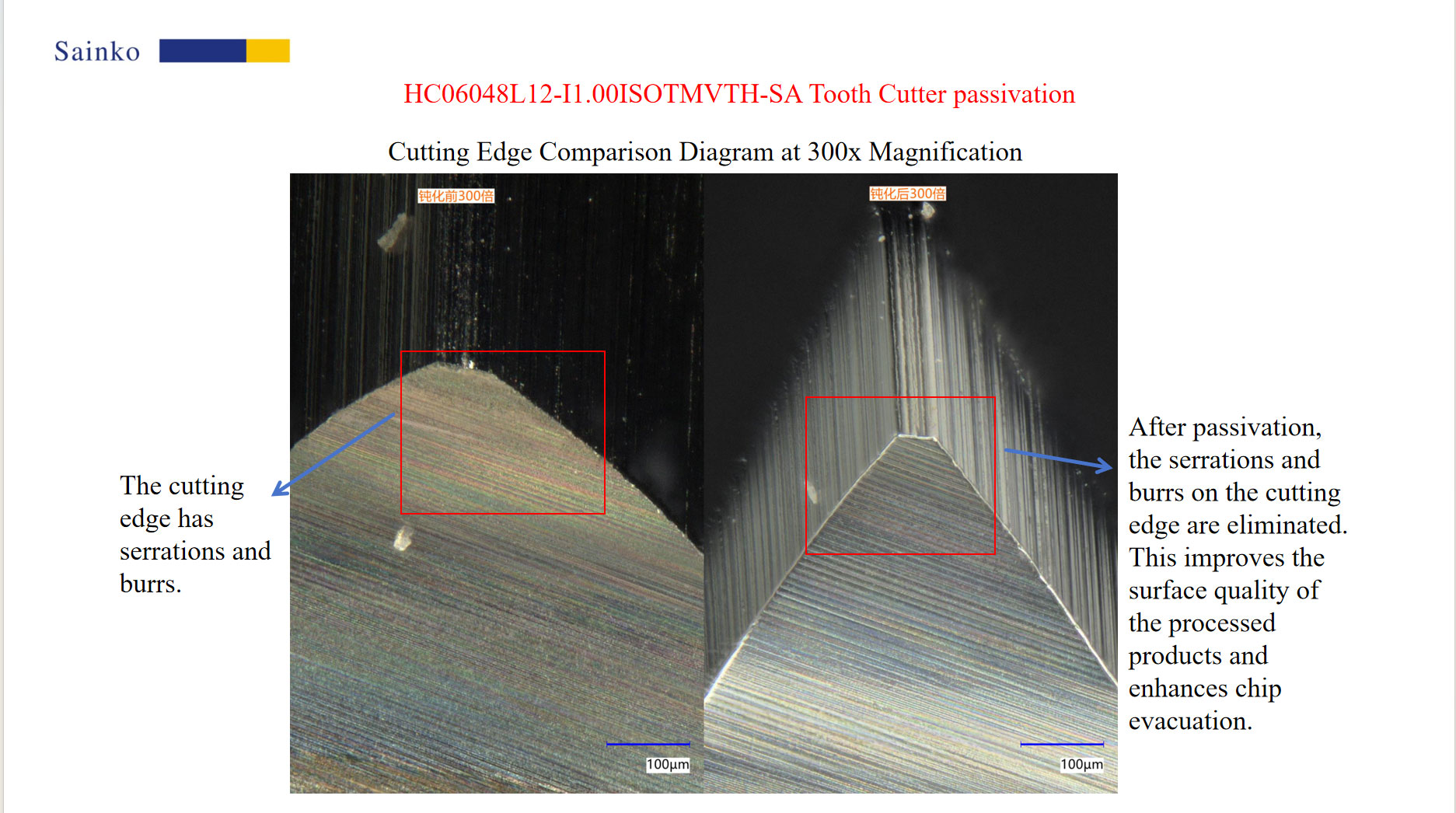

By comparative observation, it can be seen that there are obvious small serrations and burrs on the cutting edge before passivation, and the cutting edge is irregular, which can easily cause problems such as high cutting resistance and poor surface roughness; After passivation, the blade is flat and smooth, with a uniform and rounded shape, and no residual burrs. This improvement effectively enhances the surface quality of processed products, optimizes the chip discharge effect, and significantly reduces the risk of chip accumulation and workpiece scratches.

Through this passivation treatment, the overall cutting performance of the milling cutter has been significantly improved, and the stability of the tool has been enhanced, providing reliable tool support for subsequent high-precision machining. The specific test data and microscopic results are detailed in this report.